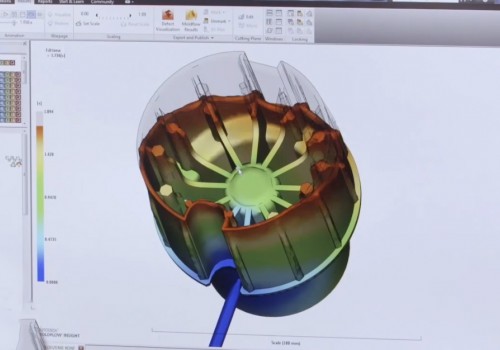

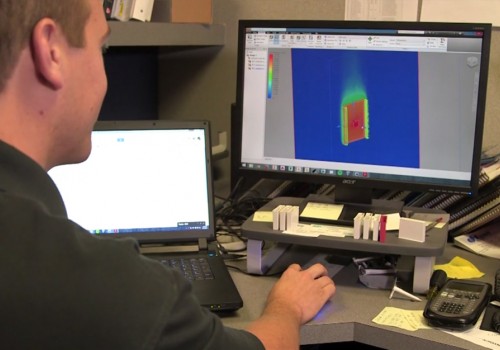

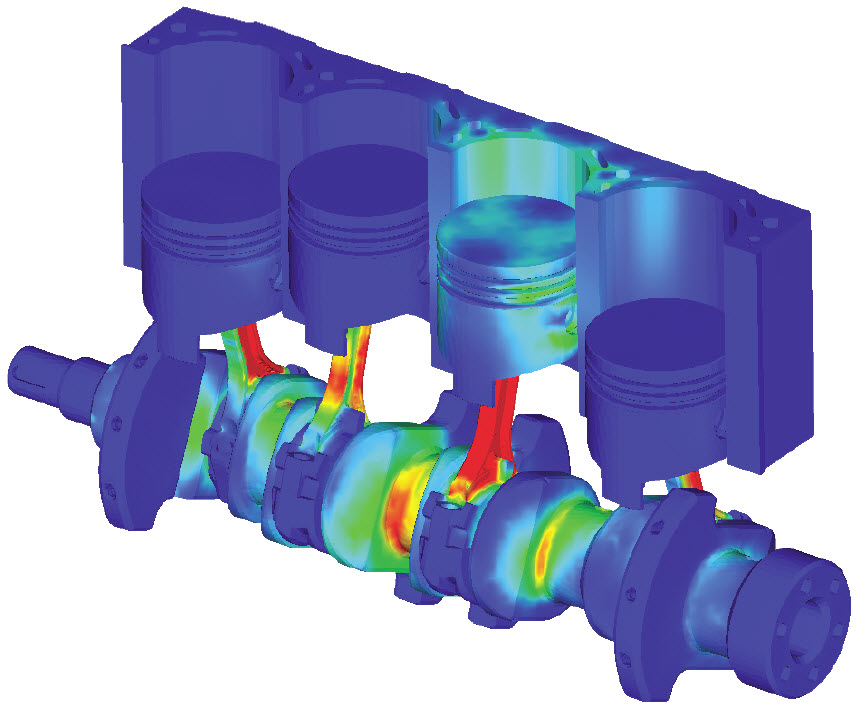

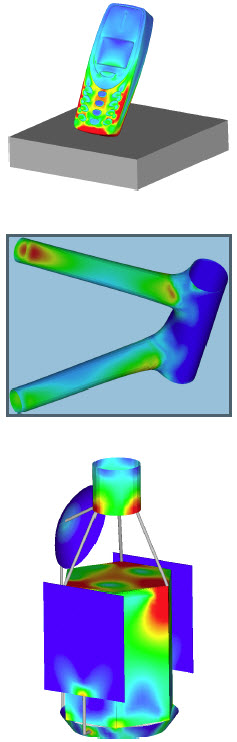

Obtain precise results to complex simulations using Autodesk Nastran, an industry-recognized FEA solver.

Accurately simulate real-world behavior with advanced mechanical, dynamics, and thermal analysis with Nastran In-CAD, a part of the Autodesk Product Design & Manufacturing Industry Collection.

Tell Us About Your Project:

This high-end simulation technology is offered as a value-enhanced package so you can obtain accurate results for complex simulations. Autodesk Nastran is the integrated solving platform for Autodesk mechanical simulation offerings.

Proven and recognized FEA technology

Computational accuracy is foremost and fundamental in a solver design. Robust software design, development methodology, and architecture avoid compromises and preserve solver precision. The Autodesk Nastran reputation for accuracy is assured by comprehensive validation with each new release and decades of real-world application history. It has achieved this level of acceptance because of its precision and the fidelity of its analysis results.

An extensive verification program and documentation set using NAFEMS and other published benchmarks helps ensure accurate solutions. Over 5,000 test problems are verified for each software release to assure consistency as well as numerous improvement updates unique to Nastran that result in unprecedented precision.

Pre- and post-processor compatibility

Pre- and post-processor compatibility

Autodesk Nastran is compatible with pre- and post-processors that read Nastran data files, such as Siemens® Femap®, MSC® Patran®, and Altair® Hypermesh®—providing engineers and analysts the flexibility to use the Nastran solver and it’s advanced capabilities with their preferred pre- and post-processors.

Scalability for future simulation needs

The Autodesk Nastran platform easily expands to additional solution types through third-party add-ons, so you can perform tasks required now and in the future with capabilities that grow with your needs. Eliminate the need to adopt a whole new FEA platform as your analysis and simulation needs become more sophisticated.

Real-time analysis and results

Real-time analysis gives engineers greater control over their FEA models and results. Features such as advanced editing, context-sensitive input, and dynamic help greatly increase productivity and results reliability from the start.

Built-in tools such as the trade study generator and parameter optimization give users quick insight into the effects of design changes. Real‑time results are displayed through an integrated results processor, so users can visualize results as they are generated during the solution sequence. These features combine to make Autodesk Nastran an indispensable solver for engineers and analysts alike.

Packaging and availability

The ease of doing business becomes a valuable factor in enabling engineers and analysts to make great products. Autodesk Nastran works with multiple pre- and post-processors; allows for multicore deployment; and offers regional and global usage rights for ease of deployment. Worldwide access to Autodesk’s comprehensive engineering tools makes Nastran easily obtainable. Nastran delivers high-end simulation technology to help you obtain accurate results for complex simulations.

Autodesk Nastran supports the following:

Linear static analysis

Linear static analysis

- Linear stress, strain, and deflection

- Inertial relief

- Thermal stress and deflection

- Multi-axial fatigue

- Mass properties

- Pre-stress

Dynamic response

- Direct transient response

- Direct frequency response

- Modal transient response

- Modal frequency response

- Random vibration

- Modal response/shock spectrum generation

- Modal summation (ABS, SRSS, NRL, CQC, DDAM)

- Linear and nonlinear direct transient response

- Linear and nonlinear pre-stress support for all modal solutions

- Vibration fatigue

Modal analysis

- Natural frequencies and mode shapes

- Flexible and rigid body motion

- Modal participation factors, effective mass/weight, and reaction forces

- Linear and nonlinear pre-stress (stiffening)

- Virtual fluid mass

Transient heat transfer

- Linear and nonlinear

- Conduction, convection, and radiation

Steady state heat transfer

- Linear and nonlinear

- Conduction, convection, and radiation

Buckling analysis

- Critical loads and mode shapes

- Linear and nonlinear initial stress

Nonlinear analysis

- Nonlinear static and transient response

- Large displacement and rotation

- Automated Impact Analysis (AIA™)

- Material nonlinear (nonlinear elastic, elasto‑plastic, perfectly plastic, thermo-elastic, visco-elastic, creep)

- Tension only (cables and shell elements)

- Contact (gap, slide line, and surface-to-surface, all with friction)

- Progressive Ply Failure Analysis (PPFA™)

- Brittle materials (concrete)

- Shape memory materials (Nitinol)

General (supported in all solutions)

- Composite laminate materials

- Temperature-dependent materials

- Direct matrix import and export (DMIG)

- Craig-Bamption and Guyan reduction

- Superelement support

- Displacement, load, and temperature interpolation

Learn more or purchase:

Access a D3 specialist who can provide product expertise, a deep understanding of your industry, and value that extends beyond your software. To license Autodesk Nastran software or subscribe to an Autodesk Industry Collection, contact D3 using the form at the bottom of this page, or call 877-731-7171. If you have questions regarding the software you already own, please contact D3's CAD support.

D3 Software Training:

As an accomplished Autodesk Authorized Reseller and Training Center, D3 offers professional public and private CAD training courses and learning plans to get you up-to-speed on your Autodesk software. Our world-class trainers know how to help your team get the most out of the applications they use and will take the time get to know how your company works to provide maximum benefit to your employees.

Additional Resources

Article

Featured Products

Featured Products