Adaptive clearing

2.5- and 3-axis milling

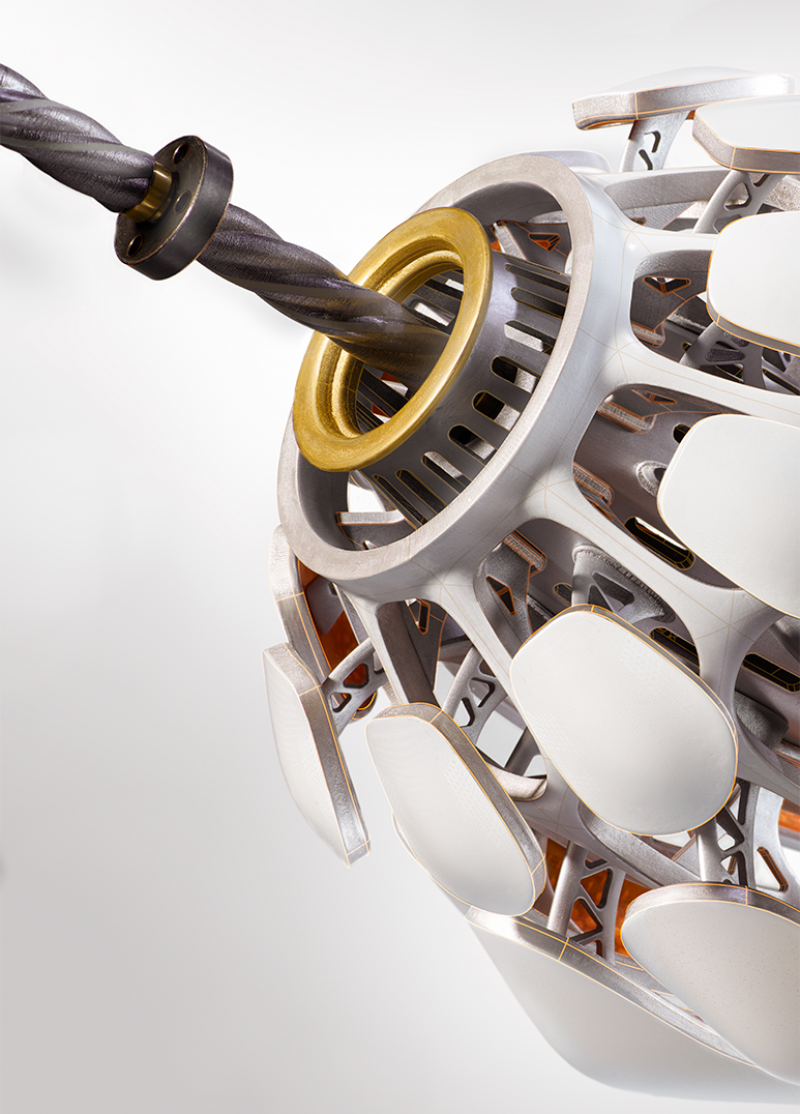

4- and 5-axis milling

Turning and mill-turn

AnyCAD in Inventor

Waterjet, plasma, and laser cutting

Probing

Tool holder avoidance

Slope machining

Stock and toolpath simulation

CNC output edit

Analysis tools