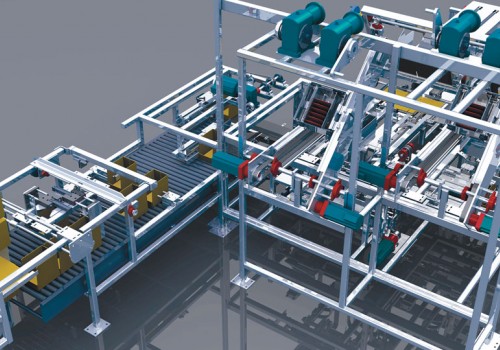

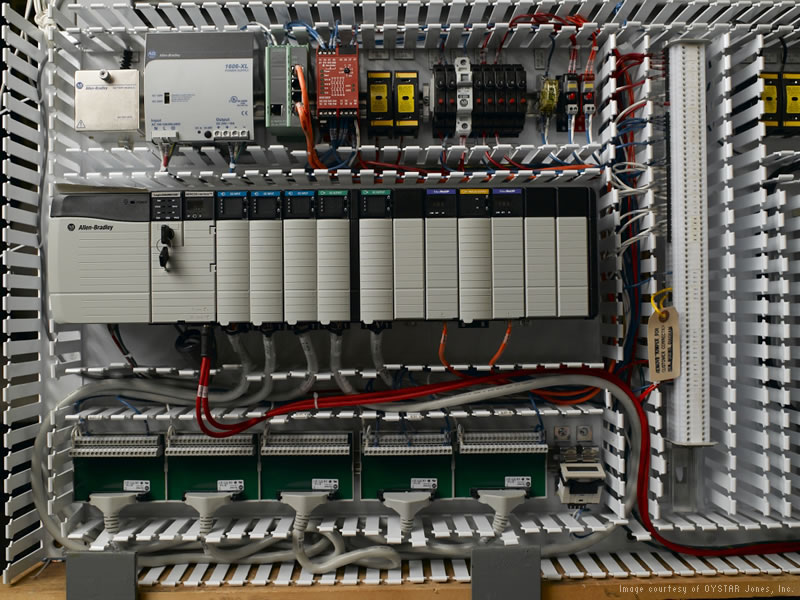

OYSTAR Jones realizes time savings of up to 75 percent in designing high-speed custom packaging equipment by using AutoCAD Electrical software.

Project Summary

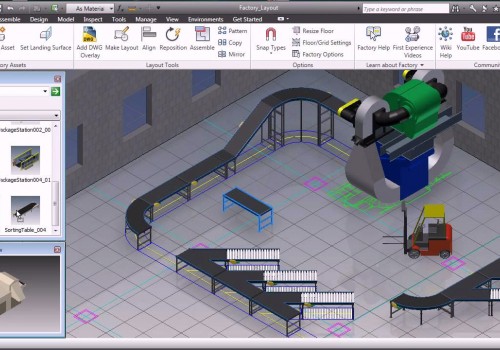

OYSTAR Jones, Inc. (OYSTAR Jones) manufactures high-speed packaging equipment for the consumer products, food, beverage, and pharmaceutical industries. To remain an industry leader, the company set out to slash its product cycle times by 50 percent, improve quality, and reduce overall costs. After using AutoCAD software for over a decade, OYSTAR Jones’s electrical engineering department looked to Autodesk to help it speed up its design process while enabling it to leverage its huge library of parts and existing designs. Thanks to its adoption of AutoCAD® Electrical software, OYSTAR Jones’s electrical engineering department is helping the company meet its aggressive operational goals. With AutoCAD Electrical, OYSTAR Jones has:

- Realized time savings of up to 75 percent

- Reduced labor costs for electrical drawings by up to 60 percent

- Produced higher quality designs

- Lowered rework and parts inventory costs

The Challenge

Like many manufacturers, OYSTAR Jones faced several industry challenges, including global competition, mass customization, and outsourcing. To compete effectively, the company needed to improve its ability to get products to market faster. OYSTAR Jones’s CEO tasked workers with cutting design cycle times by 50 percent, an aggressive goal that required the electrical engineering department to consider adopting new technology that would reduce errors and eliminate costly rework.

“With AutoCAD, we struggled with human error,” says Brian Vincent, manager of engineering at OYSTAR Jones. “The manual process for adding cross-referencing for electrical schematic documents was both labor intensive and error prone.”

“We also had an inefficient way to do bill of materials (BOMs) in conjunction with the design process,” continues Vincent. “We had to do the electrical BOMs first and then the drawings. Due to suppliers’ long lead times, we had to put parts on order early to ensure that they would arrive at the shop in time for the electricians to build the panels. This required us to go back and take the excess parts off the BOM once the electrical schematic design was completed. We needed to get it right the first time if we were going to cut our design cycle times.”

The Solution

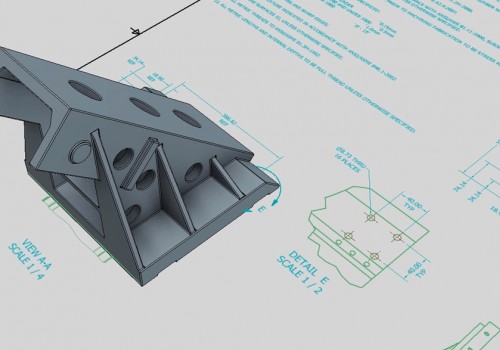

By adopting AutoCAD Electrical, OYSTAR Jones is better equipped to maintain its reputation as an elite provider of high-speed custom designs for the packaging industry. OYSTAR Jones products have a reputation for durability and long usage—a testament to the company’s commitment to quality. With AutoCAD Electrical, OYSTAR Jones is able to deliver higher-quality electrical designs in significantly less time.

Using AutoCAD, it took OYSTAR Jones three to four weeks to complete a set of drawings, due to all of the manual processes required. “It was common for us to cross-reference and perform manual checks on 40 to 50 page-long drawing packages,” explains Vincent. “There were lots of bottlenecks in the process. Each person reviewing the design marked it up and sent it back and forth, a manual process that depended on humans to check for changes in the information.”

Within the first six months of implementing AutoCAD Electrical, OYSTAR Jones was already seeing the benefits. Its drawing process is now more automated and less error-prone. “Now that we have an automated process with AutoCAD Electrical, we’ve eliminated many errors before they end up on the assembly floor,” says Vincent. “We’ve increased quality and reduced rework, helping us cut our design cycle times significantly.”

Reusing Data

When OYSTAR Jones’s electrical engineering department chose AutoCAD Electrical, it knew AutoCAD Electrical would not only introduce automation to increase efficiencies, but also allow the company to continue leveraging the DWG™ data it had been generating for decades. “We had a library of parts that we’ve been able to use within AutoCAD Electrical,” explains Vincent. “We simply updated the attributes of these parts to convert them to ‘Smart Parts.’ This functionality heavily contributed to our decision to adopt AutoCAD Electrical over the competition.”

Reducing Rework

A significant contributor to the reduction in both design cycle times and the cost of parts inventory is OYSTAR Jones’s new streamlined process for producing electrical BOMs. Before AutoCAD Electrical, OYSTAR Jones’s electrical engineers had to estimate what parts would be needed for a design before they even completed the electrical drawings. Now, teams generate designs concurrently with the BOM creation, nearly eliminating rework as well as preventing unnecessary parts purchases. “By using AutoCAD Electrical, we are able to create an accurate BOM early in the design process, saving us a great deal of time by eliminating the rework on the backend,” says Vincent. “We have more time to make sure the rest of the design is perfect because we’re not rushing to finish drawings and order parts. And now that we order the correct parts at the right time, we’ve been able to reduce our inventory.”

The Result

In describing the benefits AutoCAD Electrical delivers to OYSTAR Jones’s electrical engineering team, Vincent says, “We basically went from an ‘Etch-a-Sketch’ type CAD system to a true engineering design package when we moved from AutoCAD to AutoCAD Electrical.” Using AutoCAD Electrical has enabled OYSTAR Jones to reduce the design cycle time for a typical project from three or four weeks to just one week—a time savings of up to 75 percent. The company has also cut labor for electrical drawings by up to 60 percent and reduced parts inventory costs by 5–10 percent, which translates into thousands of dollars in savings per year.

“Using AutoCAD Electrical has not only reduced our costs, but what really stands out is the quality factor,” concludes Vincent. “We’re more confident in our work because we know it is right the first time—we won’t have to rework it later. We are certainly gaining a competitive advantage with AutoCAD Electrical.”

Learn more about AutoCAD Electrical here, or contact us using the form below.

Additional Resources

Success Stories

Success Stories

Success Stories

Featured Products

Featured Products

Featured Products

Featured Products

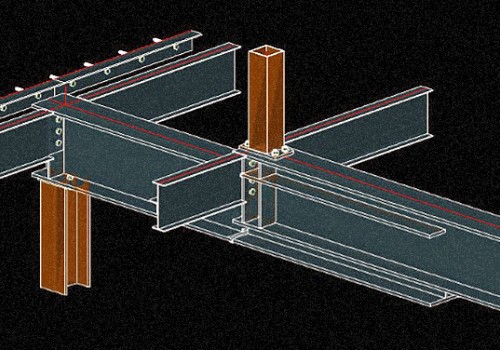

Autodesk Advance Steel for 3D Steel Modeling, Detailing & Fabrication

Featured Products

Featured Products

Article

Success Stories

Featured Products

Featured Products

Featured Products

Autodesk Architecture, Engineering & Construction Collection

Featured Products

Article

Article