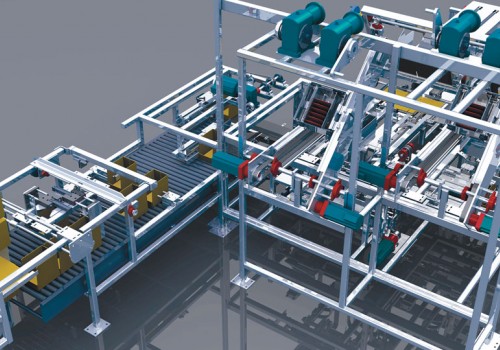

The following 5 problem areas are the most common issues we've heard from our customers regarding their factory design process. Autodesk Factory can enhance the factory design experience to solve these problems, so that you can spent less time drafting and more time optimizing and visually communicating factory layouts.

1.) Most manufacturers struggle to clearly communicate layout ideas with internal and external stakeholders.

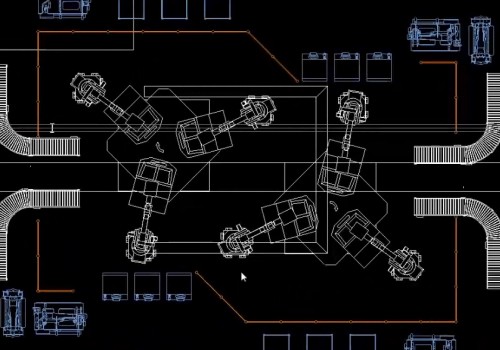

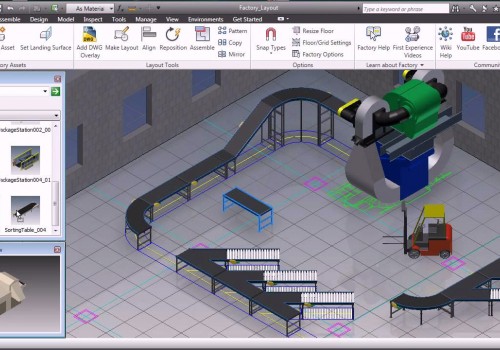

Autodesk Factory enables you to clearly articulate the design intent of your layout in 3D with internal and external stakeholders. It provides an easy to use, visual layout environment where you can drag and drop 3D factory models from a library on a floor plane allowing you to create compelling 3D layouts in a matter of minutes, significantly faster than 2D workflows. You can easily collaborate with your internal and external stakeholders and share 3D models with them for interactive 3D walkthroughs.

2.) Most manufacturers find it difficult to effectively detect clashes and identify space constraints in the 2D layout.

Autodesk Factory will identify classes and space constraints before the real equipment is commissioned on the factory floor. It provides a complete set of 3D review tools to help check for interferences using a single digital factory model.

3.) Most manufacturers spend too much time manually creating and updating plan views and section drawings of their layout.

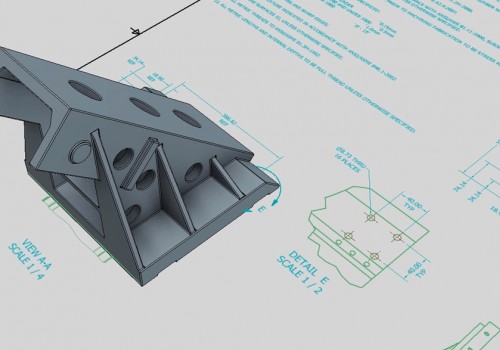

Autodesk Factory automatically generates plan views and section views of the layout which are always associative and do not need manual updates. It allows you to automatically create 2D plan views and section drawings from your 3D models; these drawings are always associative, so if the 3D model changes, the 2D documentation is always up to date.

4.) Most manufacturers spend too much time manually doing tape measurements to capture the as-built state of the facility.

Autodesk Factory eliminates or drastically reduces the time involved in doing manual tape measurements to capture the as-built state of the factory. It provides support for laser scanning workflows which allows you to design your layout directly in context of the as-built state of the facility.

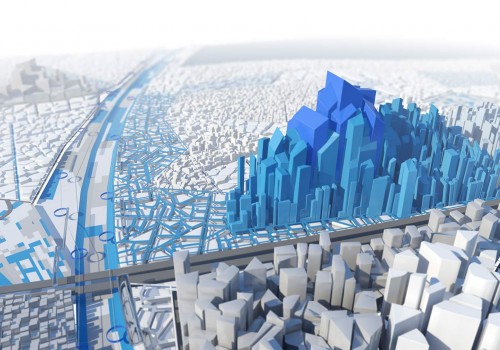

5.) Most manufacturers find it difficult to design and view large factory layouts in 2D/3D?

You can use Autodesk Factory to aggregate 3D data from different CAD systems to bring together design, manufacturing and plant and supplier data into a single digital model, allowing all stakeholders to use the 3D model to validate the design, eliminating the need to maintain or have access to different CAD systems. Autodesk Factory is compatible with all major native design and laser scan file formats so data from various sources can be combined together to create a single digital model for review, regardless of size.

Interested in learning more? Check out our on-demand webinar below where Thomas Smith, Implementation Consultant at D3, goes into more detail on what makes Autodesk Factory an essential tool for factory design.

To learn more about how you can start using Autodesk's Factory Design solution to enhance your factory design workflows, contact D3.

Contact D3 using the form below:

Additional Resources

Success Stories

Success Stories

Success Stories

Featured Products

Featured Products

Featured Products

Featured Products

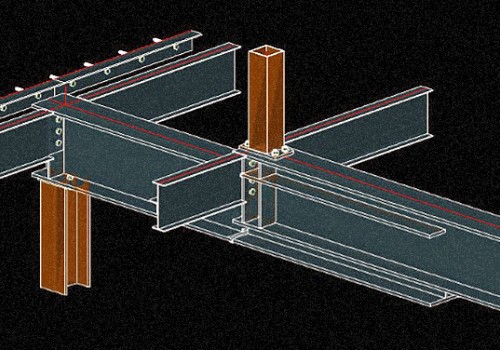

Autodesk Advance Steel for 3D Steel Modeling, Detailing & Fabrication

Featured Products

Featured Products

Article

Success Stories

Featured Products

Featured Products

Featured Products

Autodesk Architecture, Engineering & Construction Collection

Featured Products

Article

Article