Automation tools for the complex products you sell to the market.

You don't have to sacrifice what's possible just to have something that's simple to use.

Rules Engine Tool Platform from D3

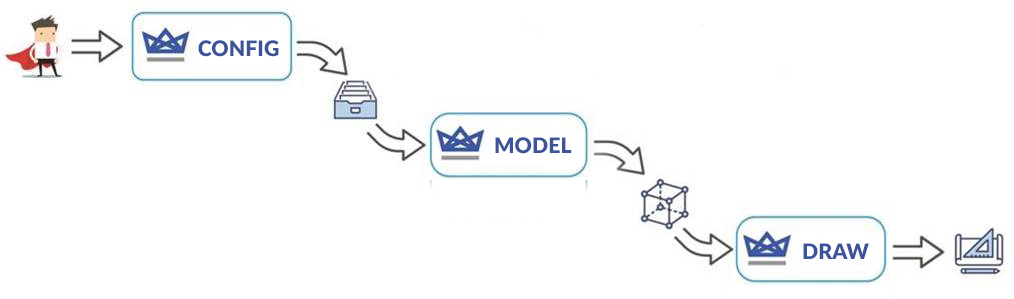

Configure, price and quote (CPQ) tools are getting a lot of traction in recent times due to the growing realization that manufacturers of complex products have to improve in order to compete. One of the key areas comes in the way you can automate the sales process. By simplifying the entry of BOM data that translates to the ERP pricing information, steps are reduced and errors are avoided. However, many companies are also realizing that they want to connect the dots to an even larger set of problems. Empower an intelligent design to be created early on in the process that will also create engineering models and drawings in addition to BOM to ERP syncing. They also want to create outputs that support the sales process along with production. CPQ can’t do that…

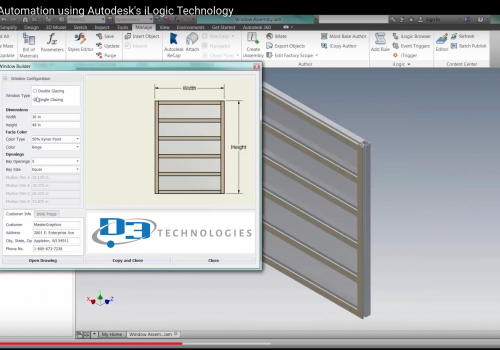

Autodesk's Inventor’s iLogic, as well as Solidworks Driveworks, are also limited in their abilities to deliver robust solutions that extend to the enterprise and want the stability of a true programming environment that can test, debug and even validate integrity before being put into production.

Ruler was born to solve these complex issues and remove risks for our clients. Ruler leverages the latest technology and have processing results that will make your face melt. It’s also CAD neutral, as we are working with both Inventor and Solidworks. This secures the path for all clients needing sophisticated tools to solve complex issues and not put their development future at risk.

When considering strategies on how to solve your problems and what the differences are between them, it may be good to review the points below. These reflect the common strategies we see being considered and they can help you understand where Ruler is the better fit, what you stand to gain by using D3 for our expertise and what the alternatives don’t offer.

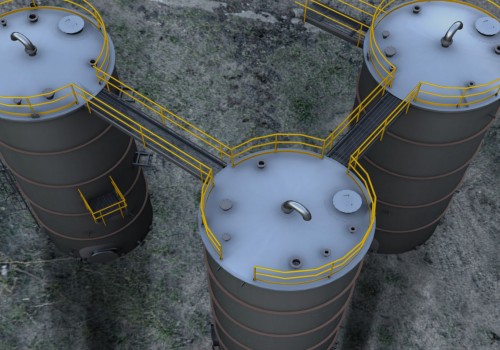

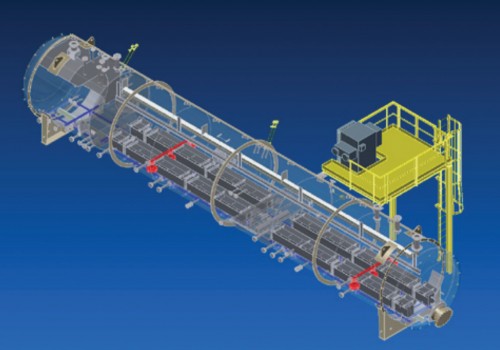

Recent successes:

- 14hrs down to 3 minutes and processing 80% of orders without being touched

- Includes models and drawings along with the BOM to ERP

- 500hrs down to 20 minutes, Revised project in 5 minutes vs 30hrs of work

- Included 15,000 model occurrences and 438 drawings without being touched

The main difference between CPQ and Ruler

CPQ requires one to have all of the model logic set up and mapped out for every configuration possible, thus the typical approach for catalogue type products vs ones that are configure-to-order or engineered-to-order. Even so, for companies that are more heavily weighted to CPQ needs but have an important amount of effort that needs more, it can still be a fit for Ruler to bolt on and extend the needs for those more configure-to-order products. Thus a blended environment vs and either or.

Something to consider:

- Amount of development time with Ruler to fully automate a sample Column Assembly including parts, assemblies, and drawings = 50hrs of development. Our Generative system requires 9 fully defined rule sets to do this (part of the 50hrs above)

- Total Source files to create for all configurations if using a CPQ approach. Library system = 45,855 individual parts, assemblies and drawings

- Compare then the 45k library files vs the 9 rules and consider not only the creation, but the upkeep when things change or the testing to debug

Other benefits over CPQ:

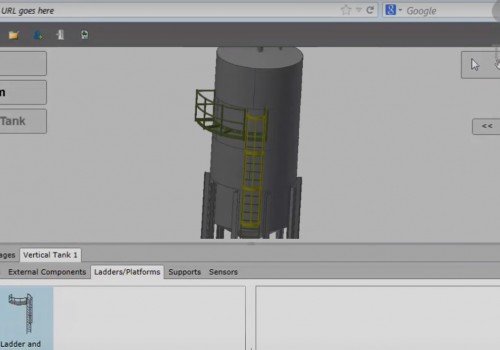

- Fully custom UI’s with 3D Model graphics and Part Level Picking from 3D model views

Benefits over iLogic

Referring above to iLogic being limited, we know that iLogic cannot handle the complexity for most engineered-to-order products. We also know that not only the complexity of the rules and size of the model are issues, but also the speed and performance. Drawings are also a big challenge to automate for iLogic but not for Ruler. When combined, these issues ultimately limit your success to gain adoption from your user base. In addition to this, here are other points to consider with Ruler.

Why is this important? :

- We were able to start with a clean slate and had our tenured experience as the backbone for Ruler

- Much faster (250x faster in some cases) because we targeted the problems our clients face

- On-premises or cloud-based, you determine that

- Direct ERP integration

- CAD agnostic, it can drive all modelers, including Inventor, Solidworks, and Autodesk Forge Design Automation.

Benefits over typical .Net team (internal or contract)

- The Ruler platform reduces the complexity of programming by up to 1/10 the amount of code.

- Our tool is built with our experience solving these challenges vs just general programming experience, so D3's team can do the work in much less time to give you a firm basis before your team takes over.

- As a solution provider, our tools come with much more detailed supporting information than a typical in-house solution and we do extensive regression testing for higher quality of deliverable.

You used Autodesk’s Inventor ETO in the past, now what?

- We used Inventor ETO for over 12 years and over 16 years of ETO.

- We did not want to see clients abandoned and solutions reduced in capabilities.

- We can also help you overcome some of the challenges you’ve faced in the past with RULER.

"The structure of the rules engine fits very well with an engineering mindset. Your calculation model can mimic your physical product and even have additional layers for abstract calculations. The WebUI and interface give the user quick feedback and provides a visual check before going through all the final processing. Having training available to encourage/enable the customer to take on the development task is icing on the cake." - Ruler Customer

Contact D3 using the form below to learn more about D3's CPQ & Product Configuration Platform:

Additional Resources

Featured Products

Featured Products

Autodesk Configurator 360: Quote & Design Automation for Simple Products

Article

Success Stories

Article

Article

Success Stories

Success Stories

Success Stories

Success Stories

Featured Products