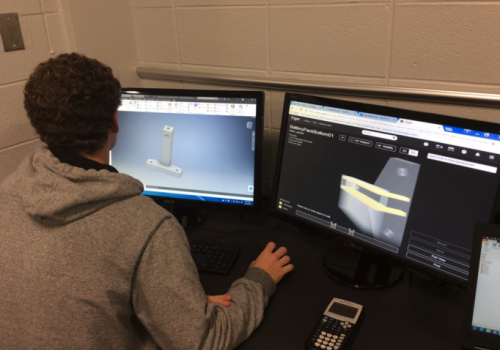

The CEO of a leading industrial equipment manufacturer in the Midwest recently said that her company sees disruption as key to their survival and growth.

"We are going to disrupt ourselves before the market does by relying on advanced technologies including 3D Printing."

This CEO has succeeded in turning around a series of product lines that had flat sales growth, using a combination of cloud platforms, analytics, mobile and rapid prototyping including 3D printing. By putting the customer at the center of these initiatives unifies the team and makes their impact on sales and customer satisfaction immediately measurable.

Based on a recent study:

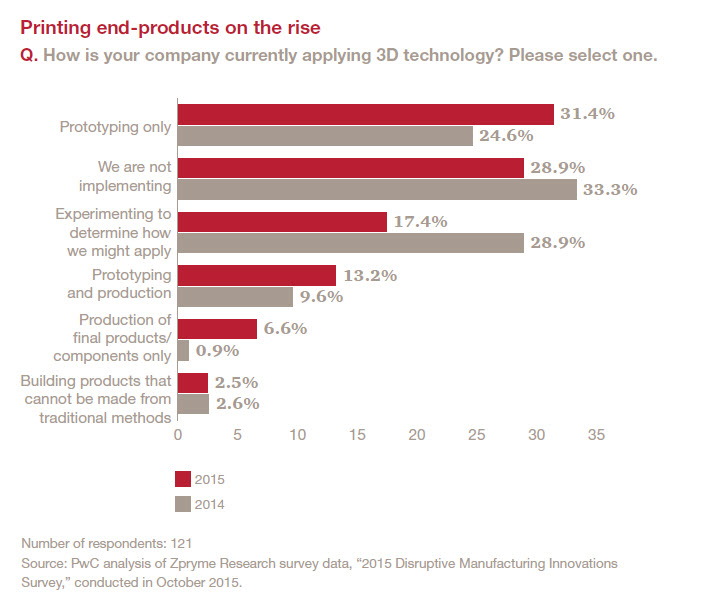

- 71.1% of manufacturers are now using 3D Printing for prototyping and final products

- 52% of manufacturers expect 3D Printing will be used for high-volume production in the next 3-5 years.

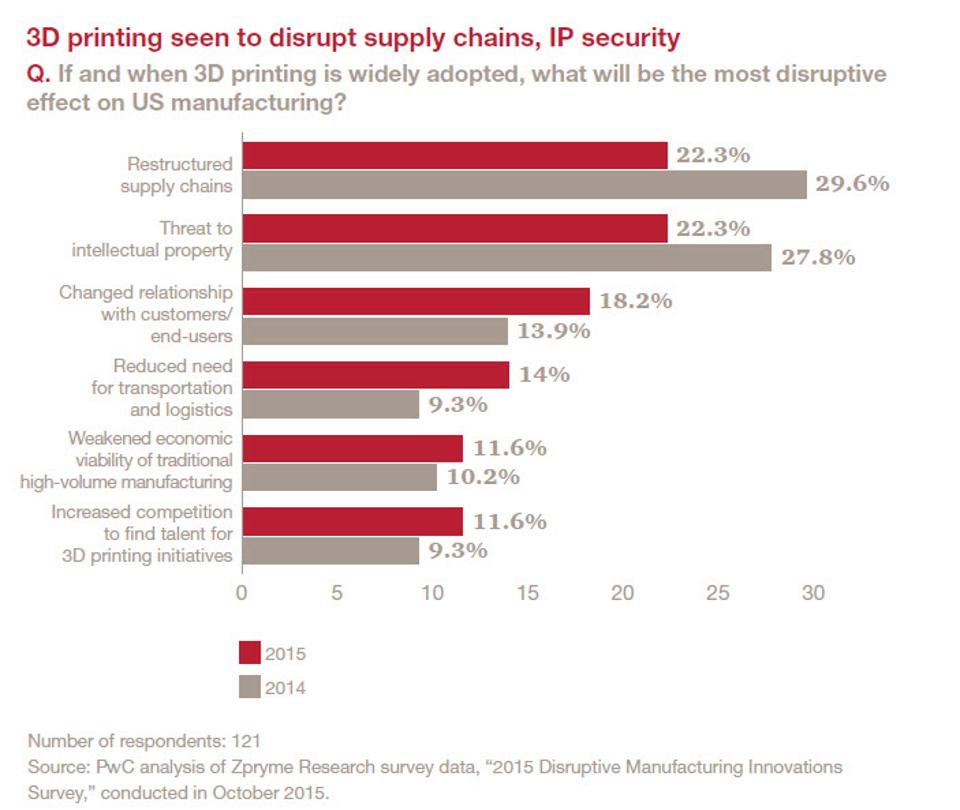

- 22% of manufacturers predict 3D Printing will have a disruptive effect on supply chains in the next 3 – 5 years.

- 52.8% of U.S. manufacturers believe that in the next 3-5 years, 3D Printing will be more useful in producing after-market parts or products.

- 64% of manufacturers expect to rely on 3D Printing for producing older, obsolete products over the next 3 – 5 years.

- 56% of manufacturers who are 3D Printing early adopters predict that more than half of their peers in the US will adopt 3D printing in the next 3-5 years.

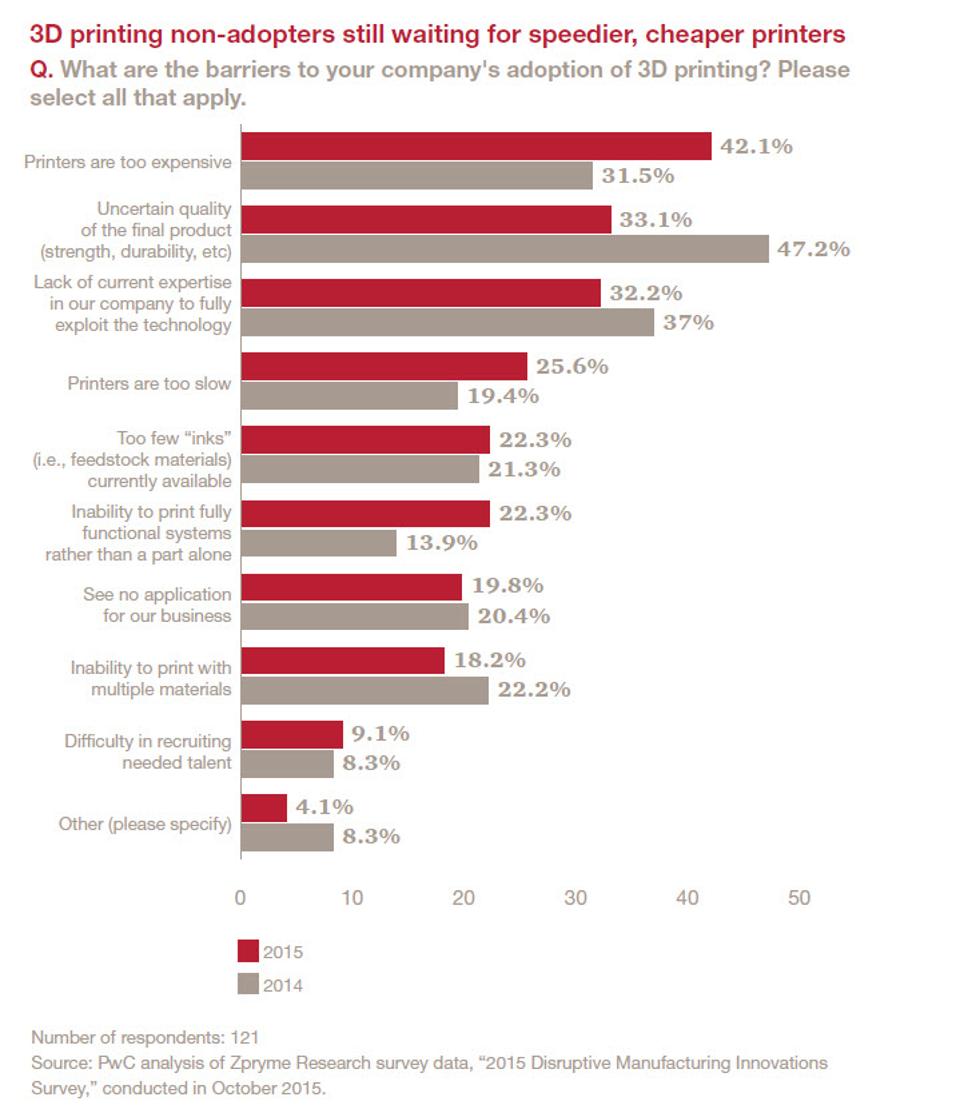

- Leading barriers to greater 3D Printing adoption in manufacturing include cost (41.3%) and lack of talent (42.1%)

Ask How You Can Own a 3D Printer Today:

Additional Resources

Success Stories

Featured Products

Featured Products

Success Stories

Featured Products

Success Stories

Success Stories

Featured Products

Success Stories

Success Stories

Featured Products

Success Stories